Packaging Solutions...

Integrated Control for Packaging

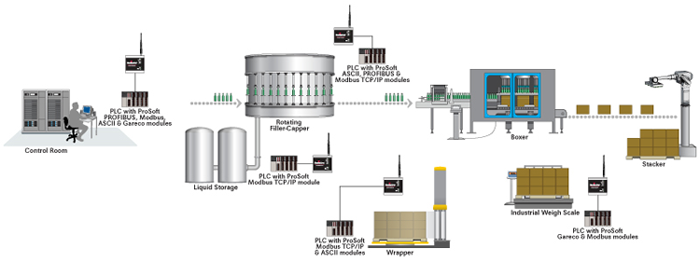

In the packaging world there is on ongoing need to integrate control architecture with packaging machinery, batch process, and manufacturing. In order to stay competitive in today's marketplace, companies must constantly streamline their processes and remain flexible enough to run smaller batches with multiple line changes on short notice. This ever-present need to do it better and faster presents a unique challenge to plant operators and packaging professionals to integrate their control systems. ProSoft Technology can help.

Factory Supervision

Horizontal integration between production, batch, process and shipping is a must for any processing/packaging plant. There is also the communication needs between motion, sequential control, drives and sensors to consider. As packaging OEMs create more efficient and cost effective machinery, the need to integrate these new machines into existing networks is crucial. The need for accurate, real-time information through an automated plant monitoring system is a must. Too often, companies find themselves burdened with outdated, legacy systems or machines and a budget that prevents them from replacing them with a state-of-the-art system.

Wireless Communication

The packaging department needs to communicate with the batch process that's making the product and the shipping department is waiting for the cartons to come down the conveyor belt. Sound familiar? In any manufacturing plant, connecting every piece of equipment across a plant, connecting to other departments and connecting the plant floor to the business-level systems is the key to increasing productivity and customer service by gathering information in real time.

However, there are usually areas where running cable to provide the needed connectivity is not feasible, is prohibitively expensive, or is physically impossible. Wireless radios can connect moving equipment including turntables, drums, gantry cranes, stacker/reclaimers, or even automated guided vehicles. ProSoft Technology's RadioLinx can help.

|

|

802.11 abg & n Access Points, Repeaters and Bridges

|

|

|

|

|

Download Packaging Industry Brochure

ProSoft Technology offers communication integration modules for a multitude of protocols

Factory Supervision

Modbus

ProSoft Technology's Modbus Modules are the fastest and easiest way to add Modbus communications capability to your plant monitoring system.

- RTU and ASCII modes

- Independently configured ports operating as Master and/or Slave

- Continuous polling of Command list

- Available as in-rack modules for Rockwell Automation platforms or as a stand-alone gateway

- Platforms: ControlLogix®, CompactLogix™, SLC-™500, PLC-5®, Quantum, and Stand-alone Gateways

Modbus TCP/IP

- 4000 word module memory usage completely user-definable

- 10/100 MB Ethernet compatible interface

- Platforms: ControlLogix®, CompactLogix™, SLC-™500, PLC-5®, and Stand-alone Gateways

EtherNet/IP

- 5000 word register to exchange data between the processor and the EtherNet/IP network

- Available as in-rack modules for Schneider Electric and Rockwell Automation platforms or as a stand-alone gateway

- Platforms: ControlLogix®, SLC-™500, PLC-5®, Quantum, and Stand-alone Gateways

Process Control Solutions

PROFIBUS DPV1 Master for ControlLogix and Quantum Platforms

- Simple-to-use ProSoft Configuration Builder software for module setup, configuration, diagnostics and debugging

- Acyclic parameter data can be transferred with Class 1 or Class 2 DPV1, allowing online parameterization, alarming and extended diagnostics

- PROFIBUS DP Master and slave interfaces also available for most Rockwell Automation platforms or as stand-alone gateways

- Platforms: ControlLogix®, Quantum

'C' Programmable Modules

The 'C' programmable Application Development Modules (ADM) provide an environment for the creation of custom applications, i.e. data manipulation, custom protocol development, complex math calculations, and data storage, which cannot be accomplished easily within a PLC. These modules are available for Rockwell Automation and Schneider Electric platforms or as stand-alone gateways.

Device Control

Connecting to end devices that may have a proprietary protocol is a constant burden to most packaging professionals. ProSoft Technology has a number of interface modules specifically designed for this purpose, including:

ASCII

- Connectivity to serial (ASCII) RS-232, 485, 422 type devices: barcode scanners, weigh scales, text displays, RFID tags, etc.

- 2 serial ports

- Read/write ASCII data

- Built-in data analyzer

- Platforms for ASCII Ethernet: ControlLogix®, CompactLogix™, SLC-™500, and PLC-5®

- Platforms for ASCII Serial: ControlLogix®, CompactLogix™, SLC-™500 PLC-5®, and Stand-alone Gateways

Gareco Protocol

- Acts as an interface for Garven Gareco Protocol High Speed Checkweigher

- Platforms: ControlLogix®, Stand-alone Gateways

DeviceNet

- Acts as an interface between DeviceNet slave devices and a Schneider Electric Quantum controller

- Platforms: Quantum