A 'Big 3' auto manufacturer increases paint-shop production by 53 percent

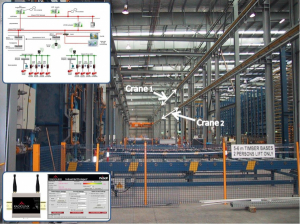

An overhead monorail system transports car body carriers around a loop that travels through the 100-meter-long paint-shop building.

At the paint-shop loading station at one end of the process line, car bodies are loaded onto these mobile carriers, lifted eight meters off the floor, and attached to an overhead monorail system. The carriers run above a process line with 14 sequential stations. At each station, the carriers stop to allow two on-board hoists to lower the car bodies into a chemical immersion bath. When the process is completed at one station, the hoists lift the car body and the carrier moves along the monorail to the next station in the chain, as soon as it's empty. After the last process station, the car bodies are unloaded from the carriers at the other side of the building, 120 meters from where they began.

The Problem – Obsolete Mobile Connectivity

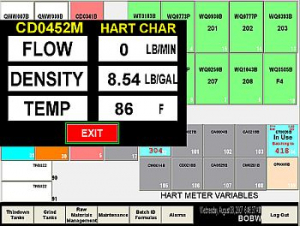

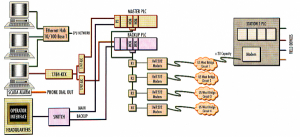

Each mobile overhead carrier contains an on-board controller to operate the on-board hoists. A single, stationary master controller located near the loading station manages the carrier controllers. The master issues commands via a legacy serial protocol through a conductor rail system that connects it to the carrier controllers.

The protocol is slower than newer industrial protocols and is difficult to transmit wirelessly. The facility management recognized that to increase communication speed and bandwidth they would need to use a new protocol. And, the original network design did not require or include peer-to-peer communication between carrier controllers. They determined that adding peer-to-peer communication capability could also help increase production.

The sliding-contact conductor rail system that carried messages came with its own set of problems. The sliding-contact system required significant maintenance to operate at peak efficiency. But even at peak efficiency, when network bandwidth utilization approached maximum capacity, high transmission error rates plagued this hardware-based rubbing connector system. Low capacity and high error rates created another problem. Even though the paint-shop process line had 14 stations, the conductor rail system had enough bandwidth for data from only 13 carriers at a time, which was restricting paint-shop throughput.

The Goal – Increase Production Capacity with Minimal Modifications

Plant engineers wanted to retain the advantages of having mobile, on-board controllers for each carrier. They wanted to eliminate the communication bottleneck imposed by the older serial protocol. They wanted to eliminate the maintenance headaches and bandwidth limitations of the conductor rail network. They wanted to be able to use all 14 stations simultaneously, and add four to six new carriers to cope with increased production demands. So, they began rethinking their network strategy.

The Solution – Marrying Old and New Technologies

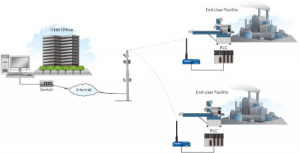

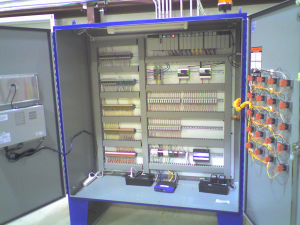

Working closely with an engineering service and local distributor, the company elected to migrate to the faster, more robust Ethernet communication network in order to increase their bandwidth capabilities. But, the processors mounted in the mobile carrier cabinets had no Ethernet ports. The manufacturer did not want to replace all the mobile PLCs with Ethernet-capable processors, so they installed a serial-to-Ethernet gateway in each controller cabinet. This enabled the stationary master processor to receive process data from the mobile processors via Ethernet. The existing legacy master PLC was replaced with a newer version, giving the master controller sufficient Ethernet connectivity bandwidth to handle the large volume of data from the mobile controllers.

The sliding contact network system was not well-suited for Ethernet communication and too unreliable and costly to maintain. Eliminating the outdated sliding contact system and replacing it with a modern wireless system seemed like an obvious and necessary choice. The mobile carriers and the stationary master controller could then communicate via Ethernet through a high-speed, high-volume wireless network solution. But wireless networks can have their own set of limitations. Radio waves reflect off metal objects and bounce in all directions, creating a potential problem known as radio multipath interference.

Engineers were doubtful wireless would be reliable for heavy industry, in an environment surrounded by moving metal. The paint shop has metal walls and a metal roof. The carriers are massive steel objects, as are the car bodies they carry. These constantly moving metal masses result in an ever-changing radio frequency environment, increasing opportunities for radio interference to interrupt or corrupt data flow. But ProSoft’s industrial radios use highly effective filtering algorithms and allow emitted power adjustment. Both of these features help overcome multipath interference problems. Plus, ProSoft Technology's expert advice regarding proper antenna selection and placement was a major factor contributing to the application's overall success.

“We saved at least 2-3 days of engineering work while designing the network,” remembers Mike Dean, the system integrator from DACs. “And of course, we saved on installation time, having less hardware to handle, manipulate, and install in the field. In fact, installation and validation of the network were very quick. When adopting a new technology, the learning curve typically runs through one or two projects. But, with [the radios] and with support from ProSoft Technology, our learning process was very short.”

The Results - DRAMATIC

Production capacity increased more than 53 percent.

The wireless radios provided all the speed and bandwidth engineers needed to achieve their design goals. Wireless networking brought the transmission speed and reliability that were missing with the old conductor-rail, sliding-contact system. The wireless solution was easy to implement and much easier to maintain, requiring less downtime. And the number of carriers that could simultaneously be in use in the paint-shop loop increased from 13 with the old network to 20 with the new network.

Learn more about ProSoft Technology’s wireless solutions here.