HART Solutions Increase Oil Production Efficiency

Venezuela is home to the Western Hemisphere’s largest oil reserves, and its economy is extremely oil-dependent. A major oil company in the country is constantly striving to remain competitive and profitable in the world energy scene.

Initial Requirements

A while back, the company conducted an analysis of their technology requirements for their oil production fields in Eastern Venezuela. The requirements identified included:

- Control system with strong third-party vendor developers and integrators

- Direct plug-in communications modules

- Use of intelligent devices (instrumentation, electrical, and mechanical)

- Open system and standard protocols on plant floor

Because of its internationally recognized brand name, the availability of future product support and its strong third party vendor/partners, Rockwell Automation was chosen to replace the end user’s legacy control system with their 1771 PLC processors. This allowed the end user to incorporate technology from some of Rockwell Automation’s Encompass™ partners, including ProSoft Technology.

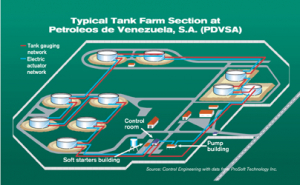

In Eastern Venezuela, the end user needed to add new tank farms, pipelines, pump and valve stations, and a SCADA system for control. Simply stated, petroleum produced at a well contains a mixture of oil, gas and water. This mixture is pumped from the pumping stations to the tank farms via a complex network of pipelines. It then undergoes field processing to separate the salable oil from the gas and water. Once the field processing is complete, 1.2 million barrels per day of crude oil are pumped through the end user’s pipeline from the actuator network to the coast for shipment to refining facilities in the United States.

Tank Gauging, Electric Actuator, and Motor Protection Relays

The SCADA system used by the end user communicates to many of its end devices via the Modbus® protocol.

The tank gauging systems monitor tank level. This data is transmitted to the Rockwell Automation processor, which automatically opens and closes valves to and from the tank. The electric actuator network controls the influx of oil from the pumping stations to the main trunk line. The end user installed medium-voltage soft starters for their control valves in order to reduce mechanical stress, starting current, and hammering.

ProSoft Technology’s single-slot Modbus interface module was used in Rockwell Automation’s 1771 PLC processors to communicate with the tank gauging systems, the electric actuator, two-wire control systems, and the motor protection relays.

A few years later, the end user used the Modbus interface in a SCADA system that was installed to control the movement of heavy crude oil from 1,500 wells in Eastern Venezuela to the coast for shipment to the U.S. for refining.

HART Multidrop module to the rescue

A few years after the SCADA system project, ProSoft was contacted by Perez-Compac in Argentina and Rockwell Automation in Venezuela, requesting their help in communicating between Rockwell Automation’s ControlLogix PLC using DF1 and numerous Rosemount end devices using the HART protocol. Representatives from three companies, including the original end user, worked together to test ProSoft’s HART gateway. Approximately 15 HART Multidrop modules underwent extensive factory acceptance testing for control of the original end user’s crude oil production units in eastern Venezuela.

“The HART Multidrop module provides maximum efficiency for HART networks,” said the ProSoft Regional Sales Manager who worked on the application.

Learn more about ProSoft Technology’s solutions for Oil and Gas applications here.